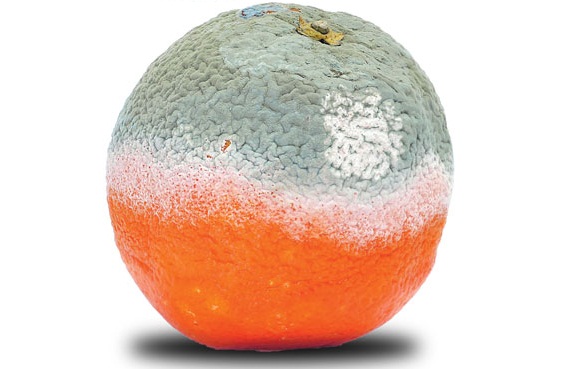

The lurking harmful effects of bacteria, microbes, fungi, molds and other pathogens on the environment and humans are latent danger that can jeopardize the modern life. Increased bacterial resistance is attributed to the misuse of antibiotics, and as a result, stronger antibiotics are always needed. According to a study, about 80% of infectious diseases start from surface contact. Bacteria and fungi are everywhere in our daily life; the microbes can quickly reproduce with suitable conditions. They may cause contamination, odors and infectious diseases and can live on all surfaces including plastic. Nowadays most home and kitchen appliances and utility products are made of plastic.

Therefore, there is a growing need for antibacterial and microbial agents due to the growing infections and their rapid transmission. Antimicrobial nano-materials are nanoscale materials that have antimicrobial properties and can prevent the growth of bacteria, microbes, fungi, molds, algae, mosses and other pathogens.

So Payesh C-One Polymer came up with an innovative solution that is Anti-Microbial Additive Masterbatch. When Anti-Microbial Additive Masterbatch is integrated into the polymer during the manufacturing process, these masterbatches inhibit the growth of microbes protecting against illnesses caused by them. This class of masterbatches contains bioside nanoparticles (deadly microorganisms) with a completely new chemical compound for the use in all types of plastics applications. These masterbatches are produced using a four-step sophisticated technique that allows for thorough dispersion and not variation in absolute particle size in the masterbatch production process. Thus, antimicrobials contents of these masterbatches are melded with all of the plastic materials perfectly, and give them an antimicrobial effect.

In these masterbatches, there is no release in the environment and are food safe, Human safe, eco-friendly and compatible with most polymers. These can be used in various processes like Injection molding, Roto molding, Extrusion, Blow molding etc to inhibit the growth of Bacteria, fungi and algae on plastic surfaces.

Depending on the initial formulation, these substances can either have each of the following properties or a combination of all.

– Anti-bacterial

– Anti-algae and moss

– Antifungal and mold

Product Description

These materials are designed and manufactured in the form of granules and powders with various plastic bases including PE, PP, PA, PC, ABS, PET, PS and PVC, in order to meet the needs and limitations of the costumers. Using very low percentages of these materials (between 2-3% by weight) in the process of mixing and molding the plastic will result in the creation of genuine and complete antibacterial components and structures.

Product Applications:

• Food packaging, Food containers

• Fridge liners

• Water tank

• Garbage bags

• Textile

• Toys

• Healthcare products

• Car interior

• Door handles

• Mobile phone covers

• Non-woven sheets

• Liners of household appliances microwaves, washing machines and air conditioners

• Toilet seats

• Toothbrushes (body and bristles)

• and etc.